When it comes to smoothing surfaces, choosing the right tool can make all the difference. You might be wondering whether a sanding screen or sandpaper is best for your project.

Both have their strengths, but which one will save you time, give you a cleaner finish, and help you avoid common mistakes? By understanding how each works and what they’re best suited for, you can make a smart choice that improves your results and makes your work easier.

Keep reading to discover the key differences between sanding screens and sandpaper—and find out which one is the perfect fit for your next project.

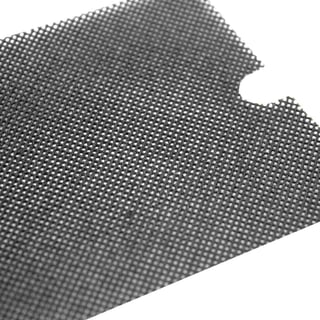

Credit: diy.stackexchange.com

Sanding Screen Basics

Sanding screens and sandpaper serve similar purposes but differ in design and use. Understanding their basics helps you pick the right tool. This section explains the material, uses, and advantages of sanding screens.

Material And Construction

Sanding screens are made from a mesh material coated with abrasive grit. The mesh allows dust to pass through easily. Sandpaper is a solid sheet with abrasive particles glued on one side. It is usually made from paper or cloth backing. The open mesh of sanding screens makes them durable and less likely to clog.

Common Uses

Sanding screens work well on drywall and plaster. They clean surfaces and remove paint or rough spots. Sandpaper is common for wood, metal, and detailed work. It smooths surfaces and shapes materials. Sanding screens are often chosen for large, flat surfaces.

Advantages

Sanding screens last longer because they do not clog quickly. They provide better airflow, reducing dust buildup. Sandpaper offers finer grit options for smooth finishes. Sanding screens are easier to clean by tapping or brushing. They also prevent scratches on soft surfaces.

Credit: www.youtube.com

Sandpaper Essentials

Sandpaper is a key tool in many projects. It smooths surfaces and removes rough spots. Knowing the basics helps you pick the right type for your task. This section covers the essentials of sandpaper.

Types And Grits

Sandpaper comes in many types. The most common are aluminum oxide, garnet, and silicon carbide. Each type works best on certain materials.

Grit size shows how coarse or fine the sandpaper is. Lower numbers, like 40 or 60, are very rough. Higher numbers, like 220 or 400, are very fine. Choose coarse grit for heavy sanding. Use fine grit for finishing touches.

Typical Applications

Sandpaper suits many jobs. It smooths wood, metal, and plastic surfaces. It also removes paint or rust. Fine grit is great for polishing. Coarse grit is ideal for shaping or stripping materials.

Craftsmen, DIYers, and painters all use sandpaper. It prepares surfaces before painting or staining. It helps achieve a clean, smooth finish.

Benefits

Sandpaper is easy to use and affordable. It comes in many sizes and types. It works well on many materials. It can be cut to fit sanders or used by hand.

It offers control over the sanding process. You can start rough and go finer. This helps avoid damage and creates smooth results.

Key Differences

Understanding the key differences between sanding screen and sandpaper helps in choosing the right tool for your project. Each has unique features that affect performance and results. Knowing these differences can save time and improve your work quality.

Durability And Longevity

Sanding screens are made from mesh material. This design allows them to last longer than sandpaper. They resist clogging and wear better. Sandpaper wears out faster due to its paper backing. It tears easily and loses grit quickly.

Dust Management

Sanding screens have open holes that let dust pass through. This feature keeps the surface cleaner. It also reduces dust buildup on the sanding tool. Sandpaper traps dust on its surface. This clogging lowers sanding efficiency and can scratch the surface.

Surface Finish

Sanding screens provide a smoother finish on rough surfaces. They remove material evenly without deep scratches. Sandpaper can leave swirl marks if used carelessly. It works well for fine finishing but is less forgiving on rough surfaces.

Choosing By Project Type

Choosing the right abrasive depends on the type of project you have. Each material needs a different approach to sanding. Using the proper tool makes the work easier and results better. Sanding screens and sandpaper both have their place. Knowing when to use each helps you finish tasks faster and cleaner.

Woodworking

Sandpaper works well on wood. It smooths rough surfaces and shapes edges. Different grits help you move from rough to fine finishes. Sanding screens can also be useful. They prevent clogging when sanding sticky or resinous wood. For detailed woodwork, sandpaper offers better control.

Metalworking

Sanding screens excel on metal surfaces. They remove rust and old paint quickly. The open mesh design stops dust build-up. Sandpaper can also polish metal but clogs faster. For heavy metal sanding, screens last longer and stay effective.

Drywall And Plaster

Sanding screens are ideal for drywall and plaster. They reduce dust and prevent tearing the surface. The mesh allows dust to escape easily. Sandpaper may clog fast and cause uneven spots. Screens give a smoother finish on walls and ceilings.

Tool Compatibility

Tool compatibility plays a key role in choosing between sanding screen and sandpaper. Both have specific uses depending on the tool you use. Understanding which sanding material fits your tool helps you get better results and saves time.

Hand Sanding

Hand sanding works well with both sanding screen and sandpaper. Sandpaper offers smooth and even surfaces for small projects. Sanding screen removes dust and debris better and lasts longer during heavy use. It is ideal for rough surfaces and quick sanding.

Orbital Sanders

Orbital sanders are designed mainly for sandpaper sheets. Sandpaper fits perfectly on the pads and sticks with hook-and-loop backing. Sanding screens can sometimes fit, but they may not stick well. This may reduce sanding efficiency and cause uneven finishes.

Detail Sanders

Detail sanders use small sandpaper pieces for precise work. Sandpaper provides better control in tight corners and edges. Sanding screens are less common here because they are thicker and less flexible. Sandpaper remains the preferred choice for detail sanders.

Credit: thediyplan.com

Cost And Availability

Cost and availability play a big role in choosing between sanding screens and sandpaper. Both have different price points and buying options. Knowing these details helps you pick the right tool for your project and budget.

Price Comparison

Sanding screens usually cost more than sandpaper. This is because they last longer and offer better airflow. Sandpaper is cheaper but wears out faster. For small jobs, sandpaper may save money. For larger jobs, sanding screens can be more cost-effective over time.

Where To Buy

Sandpaper is easy to find at most hardware stores and online. Sanding screens are less common but still available at specialty stores and some online shops. Both can be bought in various grit sizes. Choosing the right place depends on your needs and convenience.

Maintenance And Storage

Proper maintenance and storage keep sanding screens and sandpaper useful longer. Dirt and dust reduce their effectiveness. Moisture can damage them quickly. Simple care extends their life and saves money.

Cleaning Tips

Tap sanding screens gently to remove dust and debris. Use a soft brush for fine particles. Avoid water on sandpaper as it breaks the paper backing. For sanding screens, rinse lightly with water and let dry fully. Clean tools after each use to keep them ready.

Proper Storage Methods

Store sanding screens and sandpaper in a dry place. Avoid humid areas to prevent damage and rust. Keep them flat or hang to avoid bending. Use plastic containers or sealed bags for extra protection. Organize by grit size for easy access and less wear.

Frequently Asked Questions

What Is The Main Difference Between Sanding Screen And Sandpaper?

Sanding screens use mesh to remove dust and debris, while sandpaper has a solid backing with abrasive grit.

Which Tool Lasts Longer: Sanding Screen Or Sandpaper?

Sanding screens usually last longer because they don’t clog easily compared to sandpaper.

Can Sanding Screens Be Used For Fine Finishing?

Sanding screens are better for rough work; sandpaper is preferred for smooth, fine finishes.

Are Sanding Screens Reusable Compared To Sandpaper?

Yes, sanding screens can be cleaned and reused more times than sandpaper sheets.

Which Sanding Option Is Best For Drywall Projects?

Sanding screens work well on drywall because they reduce dust buildup during sanding.

Is Sandpaper Better For Woodworking Than Sanding Screens?

Sandpaper provides a smoother finish, making it better suited for detailed woodworking tasks.

Conclusion

Sanding screens and sandpaper both help smooth surfaces. Sanding screens last longer and resist clogging better. Sandpaper offers a smoother finish on delicate materials. Choose based on your project’s needs and budget. Both tools can improve your work if used right.

Try each to see which fits your style. Simple tools, big results.