Choosing the best adhesive for pool coping can make all the difference in keeping your pool edges secure and looking great. You want something that holds strong against water, weather, and time.

But with so many options out there, how do you pick the right one for your pool? You’ll discover the top adhesives that not only stick well but also last long. By the end, you’ll feel confident about making the best choice to protect your pool and enhance its beauty.

Keep reading to find the perfect adhesive for your pool coping needs!

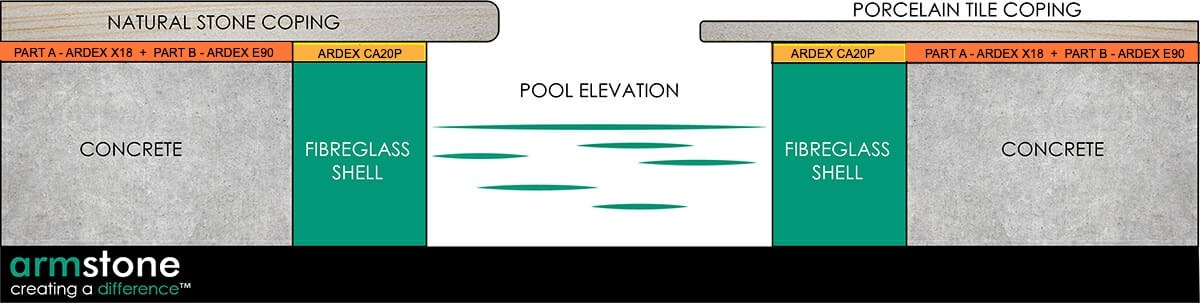

Credit: www.armstone.com.au

Types Of Pool Coping Adhesives

Choosing the right adhesive is key for pool coping installation. Different adhesives suit different materials and conditions. Knowing these types helps pick the best one for your pool. Each adhesive type has unique features and uses.

Epoxy Adhesives

Epoxy adhesives are strong and durable. They bond well with stone and concrete. Epoxy resists water and chemicals. It cures quickly and holds up under pressure. Ideal for heavy-duty pool coping projects.

Polyurethane Adhesives

Polyurethane adhesives offer flexibility and toughness. They work well on uneven surfaces. These adhesives are waterproof and resist UV rays. Perfect for outdoor use near pools. They expand slightly to fill gaps.

Silicone Adhesives

Silicone adhesives are flexible and waterproof. They are great for sealing joints in pool coping. Silicone can handle temperature changes without cracking. It is easy to apply and dries clear. Best for small repairs and sealing.

Cement-based Adhesives

Cement-based adhesives are traditional and affordable. They bond well with concrete and stone. These adhesives are strong but less flexible. Ideal for solid, flat surfaces. They need time to dry fully before use.

Factors Affecting Adhesive Choice

Choosing the best adhesive for pool coping depends on several important factors. These factors ensure the adhesive bonds well and lasts long. Understanding these points helps in picking the right product for your pool project.

Material Compatibility

Adhesive must work well with the coping material. Different materials like stone, concrete, or tile need different adhesives. Using the wrong adhesive can cause weak bonds or damage. Check the product label for material compatibility before buying.

Water Resistance

Pool areas stay wet most of the time. The adhesive must resist water without losing strength. Water resistance prevents the adhesive from breaking down or peeling off. Choose adhesives made for wet or underwater use.

Temperature Tolerance

Poolside temperatures change a lot. Adhesive must handle heat from the sun and cold nights. Some adhesives crack or soften under temperature changes. Select products with high temperature tolerance for durability.

Curing Time

Curing time is how long adhesive takes to dry and set. Faster curing means quicker project completion. Slow curing adhesives might delay the work and increase risks. Pick an adhesive with curing time that fits your schedule.

Top Adhesives For Different Pool Coping Materials

Choosing the right adhesive is key for strong pool coping. Different materials need different adhesives. Using the correct adhesive ensures durability and safety around the pool area. Below are top adhesives suited for various pool coping materials.

Concrete Coping

For concrete coping, use a high-strength epoxy adhesive. Epoxy bonds well to rough concrete surfaces. It resists water and pool chemicals effectively. This adhesive prevents cracking and loosening over time. It also cures quickly for faster project completion.

Stone And Tile Coping

Polyurethane adhesive works best for stone and tile coping. It sticks firmly to smooth and porous surfaces. This adhesive remains flexible to handle temperature changes. It also protects against moisture damage. Polyurethane helps keep tiles and stones securely in place.

Brick Coping

Masonry adhesive suits brick coping perfectly. It provides a strong bond for rough brick textures. This adhesive withstands outdoor weather and pool chemicals. It fills gaps between bricks for added stability. Masonry adhesive keeps brick coping solid and safe.

Composite Coping

For composite coping, use a construction-grade adhesive. It bonds well with plastic and wood composites. This adhesive is water-resistant and flexible. It adapts to expansion and contraction of materials. Construction adhesive ensures composite coping stays firmly attached.

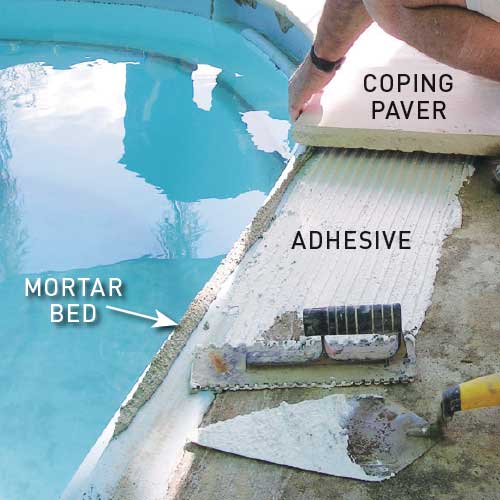

Credit: www.youtube.com

Application Tips For Stronger Bonds

Strong bonds between pool coping and the pool structure ensure durability and safety. Proper application of adhesive plays a key role in achieving this strength. Follow these simple tips to get the best results and avoid common mistakes.

Surface Preparation

Clean the surface thoroughly before applying adhesive. Remove dust, dirt, and old glue completely. Dry the area well to help the adhesive stick better. Roughen smooth surfaces slightly for stronger grip. Proper surface prep creates a solid base for bonding.

Correct Adhesive Mixing

Mix adhesive components as instructed on the package. Use the right ratio of parts for best strength. Stir gently to avoid air bubbles, which weaken bonds. Prepare only the amount you can apply before it hardens. Correct mixing ensures the adhesive works as designed.

Proper Application Techniques

Apply adhesive evenly on both surfaces to join. Use a notched trowel or spreader for uniform layers. Press the coping firmly into place without shifting. Hold the pieces steady during initial set time. Avoid excess adhesive squeeze-out for a neat finish.

Curing And Maintenance

Allow the adhesive to cure fully before using the pool. Follow the recommended curing time, usually 24 to 48 hours. Keep the bonded area dry and free from stress during curing. Inspect the joints regularly for cracks or loosening. Proper curing and care extend the life of your pool coping.

Common Mistakes To Avoid

Choosing the right adhesive for pool coping is just part of the job. Many people make common mistakes that cause problems later. Avoiding these errors helps ensure a strong, lasting bond and a beautiful pool edge.

Small mistakes can lead to loose coping or damage. Paying attention to details saves time and money.

Ignoring Surface Cleanliness

Clean surfaces are essential for good adhesion. Dirt, dust, and grease stop the glue from sticking well. Always clean the coping and pool edge thoroughly before applying adhesive. Use a brush or cloth to remove all debris. A clean surface helps the adhesive bond tightly.

Using Wrong Adhesive Types

Not all adhesives work well with pool coping materials. Some adhesives fail in wet or outdoor conditions. Choose an adhesive made for pools and outdoor use. Check the label for water resistance and temperature tolerance. Using the wrong type will cause the coping to come loose.

Incorrect Adhesive Amount

Too little adhesive weakens the bond. Too much can spill over and look messy. Apply a thin, even layer of adhesive. Follow the manufacturer’s instructions for the right amount. Proper adhesive quantity ensures a strong hold and clean finish.

Skipping Curing Time

Adhesive needs time to dry and set. Moving or stressing the coping too soon causes failure. Let the adhesive cure fully before using the pool area. Check the recommended curing time on the product label. Patience leads to a durable and secure pool coping.

Credit: pool-coping-tiles.com.au

Maintenance For Long-lasting Pool Coping

Maintaining pool coping helps keep it strong and beautiful for years. Proper care protects the adhesive and stops damage early. Regular steps make the coping last longer and save money on repairs.

Regular Inspection

Check your pool coping often for cracks or loose tiles. Small problems can turn into big ones if ignored. Look closely at the adhesive joints and edges. Early detection helps fix issues before they grow.

Sealant Reapplication

Sealants wear down over time due to water and sun exposure. Reapply sealant every 1 to 2 years to keep the adhesive safe. Clean the surface well before adding new sealant. This keeps water from seeping under the coping.

Handling Weather Effects

Sun, rain, and cold affect pool coping and adhesive strength. Protect the coping by covering the pool during harsh weather. Avoid using harsh chemicals near the pool edge. These steps reduce damage from weather changes.

Repairing Damaged Bonds

Fix any loose or broken coping tiles quickly. Remove old adhesive and clean the area before applying new glue. Use the best adhesive suited for pool coping for a strong bond. Proper repair stops water from damaging the structure.

Frequently Asked Questions

What Is The Best Adhesive For Pool Coping?

The best adhesive is waterproof, strong, and designed for outdoor use on stone or concrete.

Can I Use Regular Glue For Pool Coping?

Regular glue is not suitable because it lacks water resistance and strength for outdoor conditions.

How Long Does Pool Coping Adhesive Take To Dry?

Most pool coping adhesives dry within 24 to 48 hours for full strength.

Is Silicone Adhesive Good For Pool Coping?

Silicone works well for sealing joints but is not strong enough alone to hold coping stones.

Should Pool Coping Adhesive Be Flexible Or Rigid?

A flexible adhesive is best to handle movement and temperature changes around the pool.

Can I Apply Pool Coping Adhesive In Wet Conditions?

Some adhesives work in damp conditions, but dry surfaces ensure the best bond and durability.

Conclusion

Choosing the right adhesive keeps your pool coping strong and safe. Good glue stops cracks and holds stones tightly. It works well in water and heat. Easy to apply and dries fast. This saves time and prevents damage. Strong bonding means less repair work later.

Trust the best adhesive for long-lasting results. Your pool looks neat and stays durable. Simple steps lead to a perfect finish. Enjoy your pool without worry or fuss.